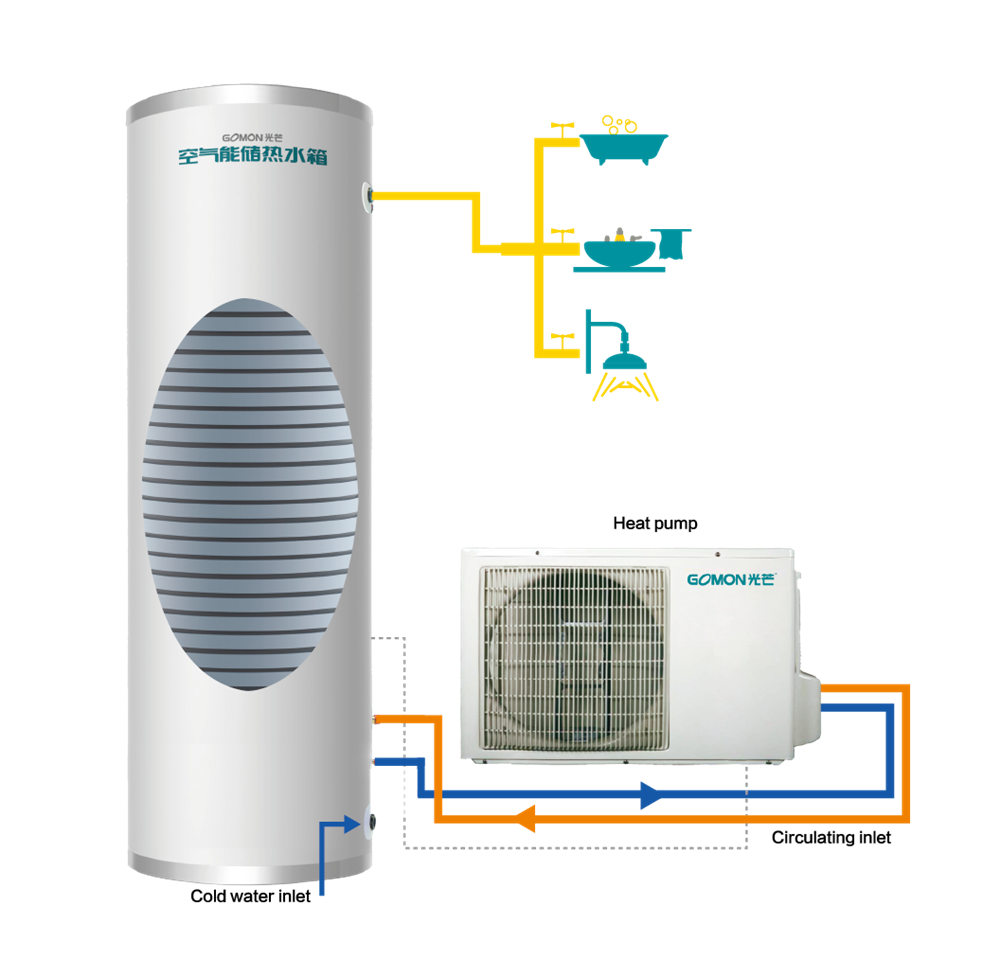

Product Description

This type of water tank applies micro-channel technology and flexible laminating process. It improves heat exchange area and heat transfer effect. System COP can reach 4.0.

Heat exchange coil does not directly contact with water, protecting coil from corrosion, scaling and leakage.

Tank applies integrated intelligent high-pressure foaming, making sure insulation layer is uniform and tight. Insulating efficiency is improved by 18%.

Enamel coated water tank is capable to endure 280,000 times' anti-pressure anti-fatigue impulse test, which guarantees a long service life of the whole system.

Technical Parameters

| Product model | 150L | 200L | 300L | 400L | 500L |

| Inner tank diameter(mm) | Φ370 | Φ426 | Φ480 | Φ610 | φ610 |

| Outer tank diameter(mm) | Φ470 | φ520 | Φ580 | Φ710 | φ710 |

| Tank Rated Pressure(mpa) | 0.8 | 0.8 | 0.8 | 0.8 | 0.8 |

| Heat Exchanger Rated Pressure(mpa) | 3 | 3 | 3 | 3 | 3 |

| Total Height(mm) | 1530 | 1530 | 1750 | 1510 | 1860 |

| Heat Exchanger Area(m2) | 1 | 1 | 1.2 | 1.5 | 1.5 |

| Insulation thickness(mm) | 50 | 47 | 47 | 50 | 50 |

| Weight(kg) | 59 | 70 | 87 | 120 | 144 |

Detail Description

Highly Sensitive With Water Mark Approved

Temperature and Pressure Relief Valves is suitable for Installing at the Pressurized solar water heater, gas heater, electric water heater , water heater of fuel, heat pump water heater , sensitive function heater, etc. various kinds of heaters( such as the boiler) and hot water containers . The valve will be opened at the set temperature(99℃) and pressure(7bar) to protect the water tank.

GOMON enamel coated inner tank applies BAOSTEEL special enamel steel plate and America Ferro enamel powder. It is produced by advanced processes including flexible CNC rolling technology, America plasma automatic welding and Germany rolling enamel technology. It passes 280,000 times' pressure impulse tests, with good performance of anti-pressure, anti-fatigue, anti-acid, anti-alkali, anti-corrosion and anti-hot water corrosion, which guarantees its service life.

GOMON enamel coated inner tank applies BAOSTEEL special enamel steel plate and America Ferro enamel powder. It is produced by advanced processes including flexible CNC rolling technology, America plasma automatic welding and Germany rolling enamel technology. It passes 280,000 times’ pressure impulse tests, with good performance of anti-pressure, anti-fatigue, anti-acid, anti-alkali, anti-corrosion and anti-hot water corrosion, which guarantees its service life.

Application